- About the spectrometer

- Applications

- Accessory

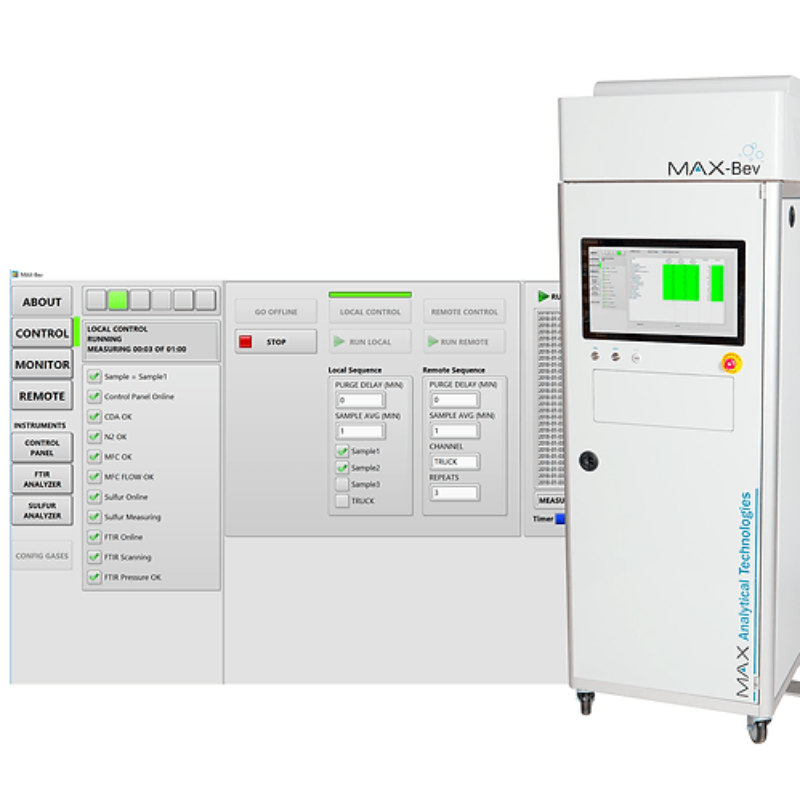

MAX Bev-CO2 is a fully automated ten-channel system dedicated to monitoring the purity of carbon dioxide (CO₂). The system is a fully integrated total analytical solution capable of measuring trace impurities in gaseous carbon dioxide (CO₂) with a detection limit in ppb units and thus declaring the absolute purity of the given gas, in parallel at ten different points in the given process. This system is based on a MAX-iR FT-IR spectrometer equipped with a DTGS detector and with a spectral range of 600–5000 cm-¹. In this range, all relevant impurities in carbon dioxide except oxygen can be detected (oxygen is handled by an optional analyzer integrated into the optional rack).

Direct online measurement of CO2 purity using MAX Bev-CO2 eliminates standard methods such as Zahm-Nagel purity testing. Using incredibly precise pressure and temperature control, the MAX-Bev CO₂ purity monitoring system is able to measure CO₂ concentration to 100 ± 0.02 % simultaneously with trace impurities including sulfur-based compounds. As part of the CO₂ purity monitoring system, the MAX-Bev is equipped with an oxidizer that converts all sulfur compounds into sulfur dioxide (SO₂), which is then measured on-line with an FTIR spectrum using the MAX-iR.

The entire MAX-Bev CO₂ gas purity monitoring system is controlled by MAX-Acquisition software, which allows you to manage all aspects of data acquisition and overall analysis, displaying system diagnostics, alarms and generating/printing certificates of analysis as well as archiving all data.

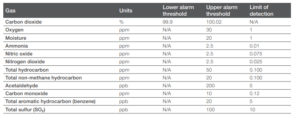

The table above shows how the MAX-Bev CO₂ monitoring system meets or even exceeds the requirements of the International Society of Beverage Technologists (ISBT) Standards for measuring key impurities in CO₂.