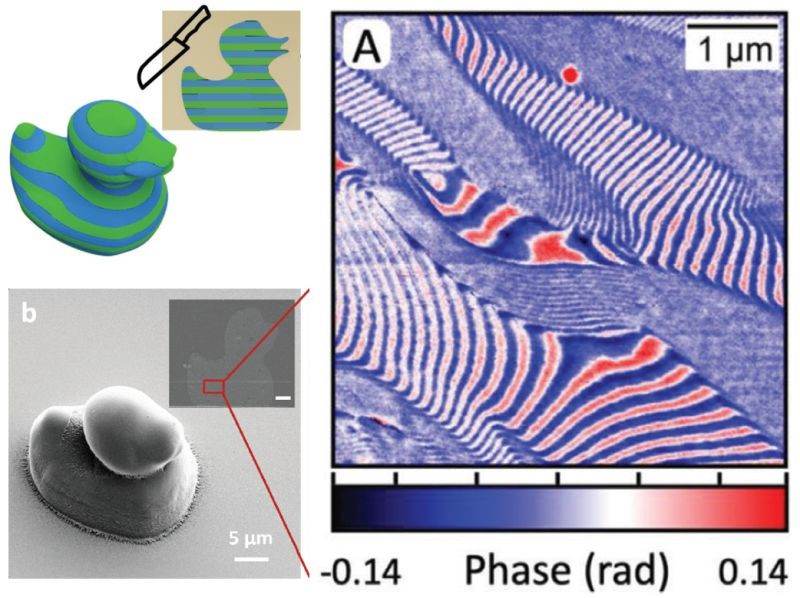

Recent advances in the field of 3D laser microprinting (micro-manufacturing, micro additive manufacturing, Micro AM) allow the rapid and reproducible production of objects of complicated shapes with sizes in the range of 50-100 nanometers. The ideal building material for many applications of this type of 3D printing seems to be e.g. the so-called block copolymers.

Block copolymers are very attractive materials, due to their potential to create self-organized structures with domains ranging from units to hundreds of nanometers in size. They are very promising candidates for various modern applications, from membrane processes, pharmaceuticals, electronics to templates (templates, knitting patterns, etc.) for nanofabrication. They are very well explored in the form of thin films, but not yet as more complex 3D structures. The creation of similar structures for future industrial control obviously requires a reliable analytical technique, and in some examples the use of only classical scanning electron microscopy is not sufficient.

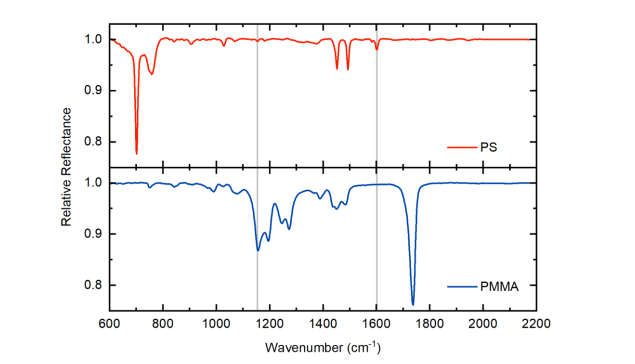

In the following example, the innovative IR-SNOM spectroscopic technique of the company Attocube (Neaspec) was used for the analysis of 3D nano ducks printed from a copolymer of polystyrene and polymethyl methacrylate: PS/PMMA. This technique uses the vibrations of these polymers in the infrared spectrum, which enable not only accurate identification of the given polymer, but also imaging of the copolymer with a spatial resolution of up to 10 nanometers.